With Thanks to 12352 Chris “chwlyms” Willmes

The fourth and final phase of MARS training began in the fall following graduation. It lasted several months, comprising classroom instruction at VENTURE, the Naval Officer Training Centre in Esquimalt, a couple of weeks at sea in the defanged minesweepers (by that time their sweep gear and guns had been removed, and they were used exclusively for junior officer training), time in the blind pilotage trainer at Canadian Forces Fleet School Halifax, and culminating in a number of weeks at sea in destroyers. The sweeper and destroyer sea phases were fundamentally the same — a mix of pilotage training (navigating in confined waters, something with which the west coast of BC abounds) and ship-handling, principally in the form of officer-of-the-watch (OOW) manoeuvres, affectionately known as “weiners.” The main difference was one of scale. The sweepers were small ships, just over one hundred and fifty feet in length, displaced a little less than four hundred tons, and fitted with a pair of diesel engines developing 2,400 SHP, were capable of breakneck speeds of sixteen knots (downhill with a tailwind). The destroyers measured three hundred and sixty-six feet in length, displaced 2,800 tons, and driven by a pair of steam turbines generating more than 30,000 SHP, had a maximum speed of more than twenty-eight knots.

One of the seamanship evolutions that we practiced over and over again was that of recovering a man overboard in a timely fashion, i.e., before the unfortunate sailor was dragged beneath the waves by a kraken, succumbed to frigid water temperatures, was eaten by a shark, or got tired of waiting to be rescued and drowned. These man overboard exercises, a.k.a. MOBEXes, required the OOW to do a number of things in a specific sequence in short order, e.g., bring the ship to rescue stations, direct the lookouts to try to get eyes on the man in the water (no easy task in higher sea states, or at night) all the while getting the ship turned around and headed back towards the presumed position of the man in the water, at which point the OOW would order the sea boat launched to effect recovery.

oscar goes for a swim

A MOBEX begins with tossing over the side Oscar, who was not the young MARS IV making inadequate progress in his training, but a life-sized dummy named for the signal flag OSCAR, which in the International Code of Signals means “man overboard.” On sighting Oscar, the lifebuoy sentry stationed back aft on the quarterdeck would toss a kisbie ring in the water and sound the alarm. The OOW would do OOW stuff, the sea boat’s crew would muster on the boat deck and prepare to launch the sea boat, a rescue diver would clamber into his wet suit and get ready to go swimming for the man in the water, etc., etc.

Before engaging in full-bore MOBEXes, our training focussed on just the ship-handling aspect of the evolution. So all that would happen is that a kisbie ring would be tossed overboard, and then the OOW under training would manouevre the ship to bring it back to where the kisbie ring had been thrown overboard, such that the kisbie ring was brought under the lee of the ship, i.e., downwind, and therefore, sheltered, on the starboard side — the same side as the sea boat — with the ship barely moving. A sailor on the quarterdeck, wielding a long boat hook, would fish the kisbie ring out of the water. The exercise would be repeated to give as many MARS IVs a go as time permitted.

When the alarm was raised, the OOW would order an increase in speed, typically to twenty-five knots, and then execute a Williamson turn. In this manouevre, the ship’s course is altered sixty degrees to port (or to starboard, depending on where the wind is, so as to put the “man in the water” under the ship’s lee on the starboard side) and then immediately reverse the helm and bring the ship all the way around to the reciprocal of the ship’s heading at the time the kisbie ring was thrown overboard. Done correctly, at the completion of the turn the kisbie ring would be very fine on the starboard bow, several hundred yards ahead. At this point, hopefully the OOW would have the kisbie ring in sight, and could make small course adjustments to bring the “man in the water” down the starboard side, very close aboard, but without running him down, which was generally considered a sub-optimal outcome. The OOW would also reduce speed, so that the ship slows to a crawl just as the kisbie ring comes alongside, rather than racing past it at a great rate of knots, which would frustrate the efforts of the sailor tasked with fishing the kisbie ring out of the water.

For these kisbie ring approach drills, half a dozen or so of us MARS IVs would be mustered on the bridge to try our hand. The Williamson turn is pretty much sailor-proof; as long as you have the mental agility to calculate the reciprocal of the course you were steering before you started the turn, the kisbie ring/“man in the water” will be right where you want him to be when you come out of the turn. The trick is taking the way off the ship at the right moment. The destroyers had relatively fine underwater hull forms, i.e., they were long and slender, and would glide a long distance through the water, unlike the minesweepers, which weren’t and didn’t.

Rich Gimblett’s half-hull model of HMCS ST LAURENT, made for him by Richard Greenwood, shows the fine underwater lines of the destroyer hull

You didn’t want to apply astern power to slow the ship, because if a boat was being launched for either a MOBEX or a real man overboard event, the propellor wash could cause problems for the boat, and/or the man in the water.

These drills were typically done at lunchtime, because the ship’s company likes the ship to be manoeuvring violently while they’re eating their lunch; it really adds to the “on the briny ocean tossed” experience. One fine noon hour, a group of us were up on the bridge, nervously awaiting our turn at the con, and fervently wishing we were down below having our spaghetti and meatballs tossed in our laps like everyone else. It was a bright sunny day, the winds were light, and there was hardly any sea running, so keeping the kisbie ring in sight wasn’t going to be an issue. Three or four of us had taken our turns, with reasonable success, i.e., the “man in the water” didn’t pass through the screws. Next on deck was SLt Jack Aubrey (not his real name, and in any event, he was a DEO, not a bud). Aubrey was extremely intelligent, but he had a propensity for getting lost in thought and would thus part company with what the zoomies call “situational awareness”, often at inopportune moments. Jack took the con, and once the captain (who was on the bridge supervising the drill) was satisfied that all the players were in their places and ready to play, passed the word back to the boat deck where a sailor was standing, kisbie ring in hand, waiting to toss it in the water. He did so, the alarm was raised, and Jack dutifully rang on twenty-five knots. The ship quickly accelerated, and about twenty or thirty seconds after the kisbie ring was tossed overboard (most of which time would have been taken up by Jack figuring out whether to start the Williamson turn to port or starboard) Jack ordered the helmsman to apply helm in the appropriate direction. Jack stopped the turn at precisely sixty degrees off the initial heading, and ordered the helmsman to apply helm in the opposite direction. The ship came around, and Jack steadied it up bang on the reciprocal heading. And there, fine on starboard bow, was the kisbie ring, gently bobbing on the waves.

Once steadied up, the ship continued to accelerate towards the kisbie ring. The captain, standing close by Jack to coach him as necessary, noticed that Jack appeared not to appreciate how rapidly the distance between the ship and the kisbie ring was decreasing, and so quietly reminded him, “now Mr Aubrey, don’t forget your speed.”

At this point, a short digression into the propulsion arrangements of a destroyer is necessary for a proper understanding of what happened next. (MARE types in the audience, and those MARS types who didn’t sleep through the engineering lectures may skip this paragraph.) The destroyers had two steam turbines driving two screws. A pair of boilers provided the steam to turn the turbines, but most of the time, only one boiler would be “flashed up”, i.e., online, as a single boiler could provide sufficient steam to drive the ship at twenty-four or twenty-five knots. The other boiler would only be flashed up in situations where full power was required, or when the redundancy of having both boilers online was required as a safety precaution, e.g., manouevring the ship away from or into a berth, navigating in confined waters, or manouevring close aboard another ship, as in a replenishment-at-sea (RAS). Each boiler had six fuel registers that injected fuel into the furnace; the number of registers in operation depended on the amount of steam required. The registers were supplied by multiply-redundant fuel pumps. Each boiler had a turbo-blower to force air into the furnace. And there were multiply-redundant pumps that fed water into the boiler to be turned into steam. All of this equipment, plus other auxiliary machinery, was for the most part controlled manually. When steaming on a single boiler, three or four stokers managed the boiler and all of the associated auxiliary machinery in the boiler room. With both boilers online, twice as many stokers would be closed up. Over in the engine room, each turbine had a stoker to operate its ahead and astern throttles, and a chief oversaw the entire engine and boiler room operation. Operating the plant required balancing the amount of steam generated by the boiler(s) to match the throttle positions of the turbines; and steam production required just the right proportions of water, fuel, and air. The actions of all the watchkeepers in the engineering spaces was closely coordinated, and in situations where the ordered power levels changed rapidly, it would become quite the frenetic dance.

Back on the bridge, our hapless hero, SLt Aubrey, hasn’t hoisted in the captain’s subtle hint to reduce power. The ship was bearing down on the kisbie ring at a great rate of knots. The time for subtlety having passed, the captain announced in a more authoritative tone, “Mr Aubrey, the ship is going to overshoot the kisbie ring, if you don’t take the way off right now!” Jack’s mind returned to the task at hand, summed up the situation, and he ordered “stop both engines.” Going from twenty-five knots to zero nearly instantaneously requires some fast and furious footwork in the engine and boiler rooms. The throttle watchkeepers close the throttles on the turbines; thus deprived of steam, the turbines spin down. Over in the boiler room, fuel to the boiler is reduced to the minimum, with just a single register operating, but the feed water can’t be shut off immediately because there is still a lot of heat in the furnace, and shutting off the water that absorbs all that heat would damage the boiler. So steam generation does not stop immediately. The boiler room watchkeepers scramble madly to divert the excess steam to steam-driven auxiliary machinery such as the turbo-alternators, the turbo-blowers, the coffee maker, etc., etc.

Unfortunately, this order was too little, too late. Up on the bridge, Jack, the captain, and a whole raft of onlookers watched as the kisbie ring went racing down the ship’s side. “Mr Aubrey, you’re overshooting the kisbie ring” exclaimed the captain, a fact that was obvious to all and sundry, with the possible exception of Jack. Our hero considered the situation and the captain’s observation, and formulated a plan. “Half astern both engines” he ordered. Unfortunately, it had slipped his mind that when the exercise began, after he had ordered half ahead both engines, he ordered propellor shaft revolutions of 186 per minute, which would propel the ship at twenty-five knots. That order for 186 RPM was still in effect when Jack ordered astern propulsion; the maximum RPM that the turbines could turn going astern was 120, so effectively Jack had ordered the maximum astern speed. The throttle watchkeepers began opening the astern throttles as rapidly as they could. This action doubtlessly caused no small amount of consternation in the boiler room. There, the watchkeepers had managed in just a few seconds to bring the boiler’s steam output down from its maximum to its minimum, and successfully diverted all of the surplus steam, without lifting the boiler’s safety valve. Now the engine room, at Jack’s behest, was demanding the maximum again, so the stokers had to ramp up the turbo-blower, fuel pump, and feed water pump as fast as possible, and open up all of the boiler’s fuel registers. Shifting from maximum steam output, to minimum, and back to maximum in the span of about forty-five seconds was running the boiler room watchkeepers ragged. Up on the bridge, we began hearing a deep rumbling reverberating up the funnel. It was not the stokers complaining, but rather, fuel was being fed into the boiler faster than the turbo-blower could be ramped up to provide sufficient air to fully combust that fuel; as a result, the fuel splashed onto the red-hot firebrick lining the floor of the boiler, where it combusted noisily and with some violence. The rumblings were accompanied by huge volumes of black smoke, which came roiling up out of the funnel, and, thanks to the minimal relative wind, wafted gently across the deck, depositing oily soot all over the place.

But now everyone’s attention was focussed astern. The ship had overshot the kisbie ring by about a hundred yards. However, with maximum speed astern rung on, the ship had rapidly come to a stop, and was now gathering considerable sternway. (In layman’s terms, we were backing up really fast.) We watched in fascination as the kisbie ring, tossing about in all the foam boiling up under the ship’s transom, disappeared beneath the ship.

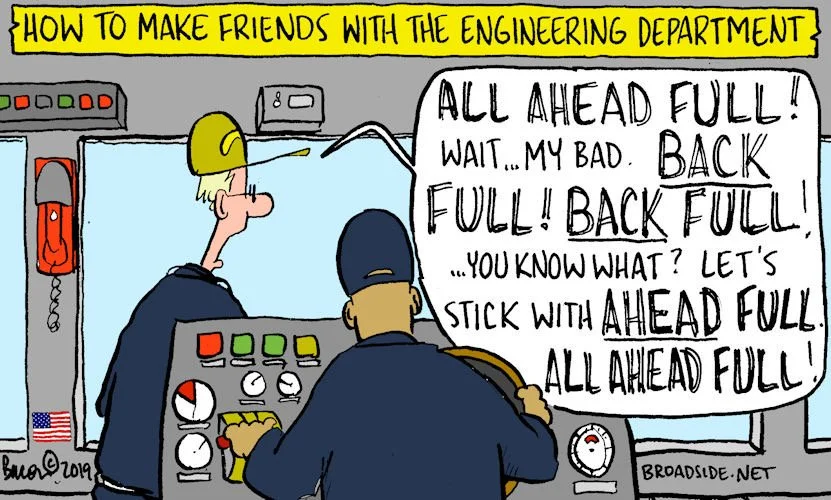

“Mr Aubrey, would you please just stop the damned ship?” suggested the captain, apparently vexed. Jack dutifully ordered, “stop both engines.” This was the proverbial straw that broke the proverbial stoker’s back. From maximum steam output, to minimum, to maximum, and back to minimum again, all in the span of about forty-five seconds, was too much for the boys in the boiler room. Try as they might, they couldn’t find a home for all that steam. Up on the bridge, we heard a low hiss emanating from the funnel. That ominous-sounding hiss rapidly increased in volume, and then, boom! The safety valve on the boiler blew, and huge jets of steam came roaring out of the steam vents on the funnel. After several seconds of deafening roaring, the pressure in the boiler dropped sufficiently for the safety valve to reseat itself, and the roaring stopped. At which point the captain, exhibiting the patience of Job, said “Mr Aubrey, I think that that will do for today. Please carry on, and go report to the Engineering Officer; I expect that he will want to speak to you about abusing the machinery.